Our Services

Welding Inspector

Iridium Industrial employs CWB Certified Level 2 visual inspectors, AWS certified Welding Inspectors, API 510 Pressure Vessel Inspectors, API 570 Pressure Piping Inspectors and API 1169 Pipeline Construction Inspectors.

Whatever the project, we have the experience and know-how to be assets in your strategy for bringing your project to a safe, timely and budgeted execution. Our inspectors can be available to attend your project or consult on specific issues remotely, depending on client requirements.

Coating Inspector

Our NACE/AMPP Certified Coating Inspectors bring a broad background and knowledge base to our technical services team. From new construction through to maintenance and integrity, our inspectors exhibit professionalism and ensure high standards of safety and quality are achieved and maintained.

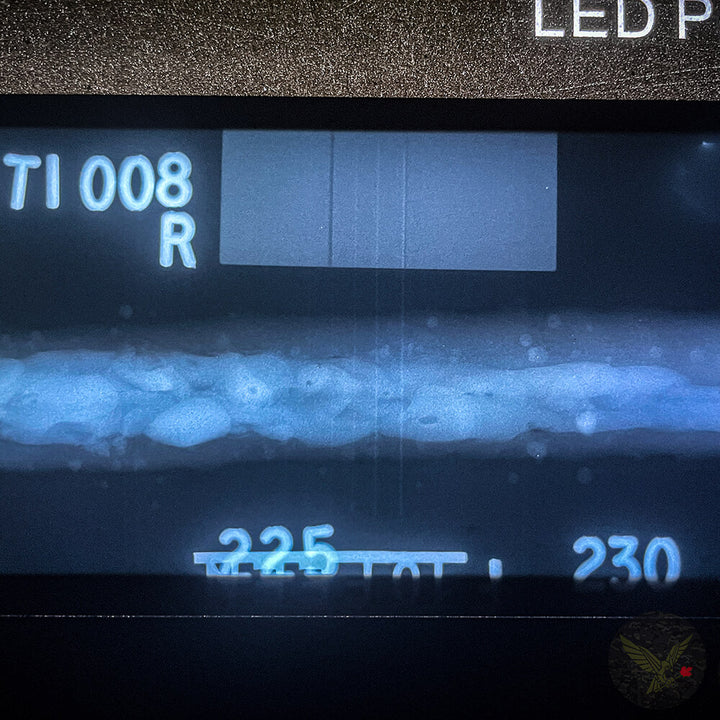

Non-Destructive Examinations of Technical Items

Ed Hubbell is a CGSB (Canadian General Standards Board) Level 2 technician in Industrial Radiography, Ultrasonics, Magnetic Particle, Liquid Penetrant and Xray Fluorescence.

Ed is a licensed Security Professional, Body Armour Salesperson and Firearms Instructor in the Province of BC. Ed has a strong background in Physical Security and Tactical Radiation Protection. He holds API 577 Metallurgy Professional certification and combines these skillsets to provide executive services to his clients.

Ed is available to perform nondestructive evaluations for special projects involving firearms, body armor and the defense sector.

Non-Destructive Examination Auditing

Ed Hubbell is a CGSB (Canadian General Standards Board) Level 2 technician in Industrial Radiography, Ultrasonics, Magnetic Particle, Liquid Penetrant and Xray Fluorescence. Ed has a broad depth of experience in the Oil&Gas, Energy, Hydro, Marine, Pulp&Paper and Infrastructure sectors. He has specific expertise in pipeline projects: both in new construction and integrity/replacement roles.

Ed is available to perform third party auditing on industrial radiography projects and radiographic film, ensuring radiation safety standards are adhered to and film quality meets or exceeds industry and client specifications.

Xray Flourescence Analyzer Operator Training Course (Level 1)

Iridium Training is an Authorized Training Organization (ATO) for Natural Resources Canada (NRCAN).

This 5hr course is the pre-requisite to challenging the CGSB Level 1 XRF exam and obtaining certification.

It is taught in-person and focuses on safety, core competencies and practical applications.

Level 1 Operators are certified to operate analyzers professionally, write XRF techniques, sign reports and audit other XRF work.

Xray Fluorescence Analyzer Operator Training Course (Level 2)

Iridium Training is an Authorized Training Organization (ATO) for Natural Resources Canada (NRCAN).

This 3hr add-on course is the pre-requisite to challenging the CGSB Level 2 XRF exam and obtaining certification. The level 2 operator holds all priviledges of the level, but is also able to teach the applicable NRCAN training courses.

In order to take this course, the student must have completed a Level 1 X-Ray Fluorescense Analyzer Operator Training Course at an NRCAN Authorized Training Organization.

Xray Flourescence (XRF) Lead (PB) Testing

Have a certified XRF technician bring a handheld analyzer to your location to test for and detect lead paint, residual lead traces in soil and on surfaces, or lead contamination in foreign products.

This service is valuable to clients with concerns for existing structures/items/equipment with coatings dating further back than 1980, as well as to items produced in foreign jurisdictions that require validation as being lead-free.

Additionally, this service can be used to screen ground, walls and other equipment surfaces after lead removal and/or lead remediation, to provide third party confirmation of adequate removal of lead and ensure compliance to health, safety and environmental standards.

Results will be professionally reported with quick turnaround and/or adhesive warning labels will be applied to lead-bearing surfaces.

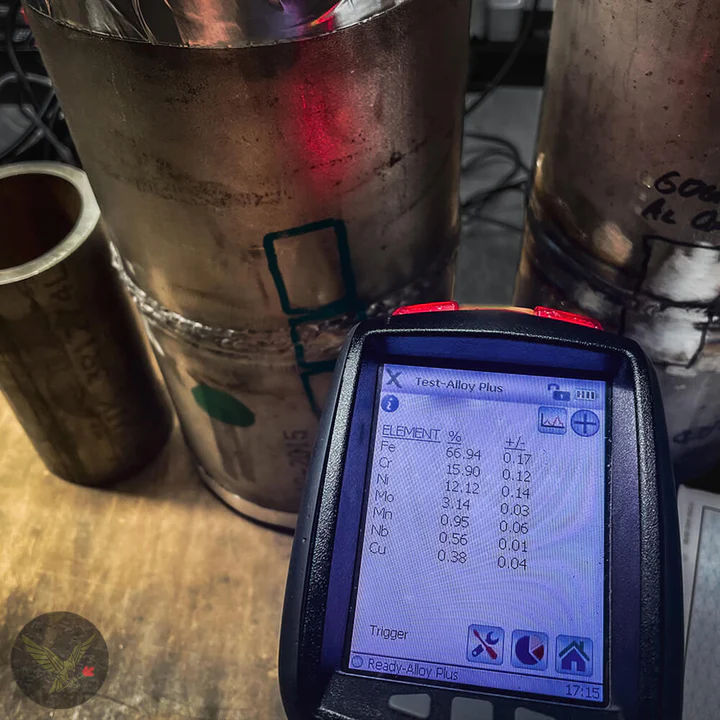

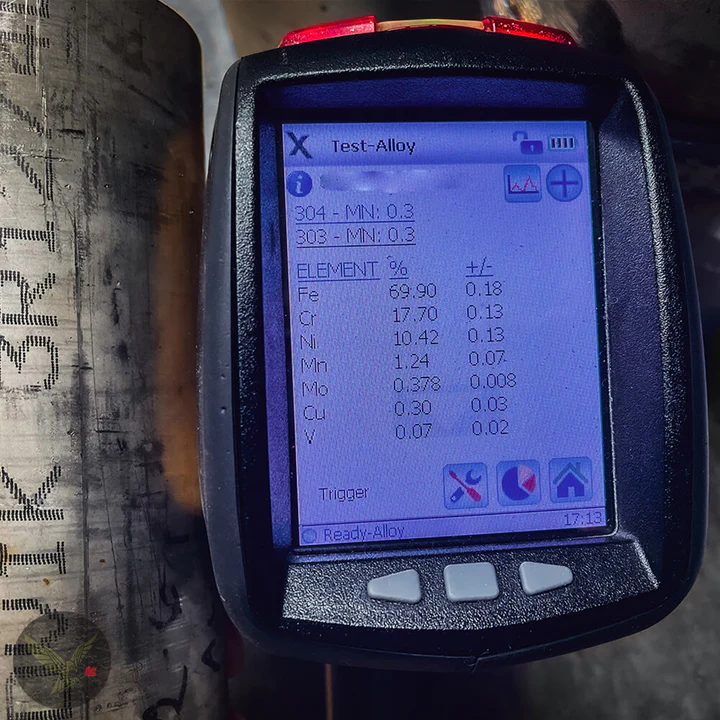

In-House Alloy and Non-Ferrous Material Testing

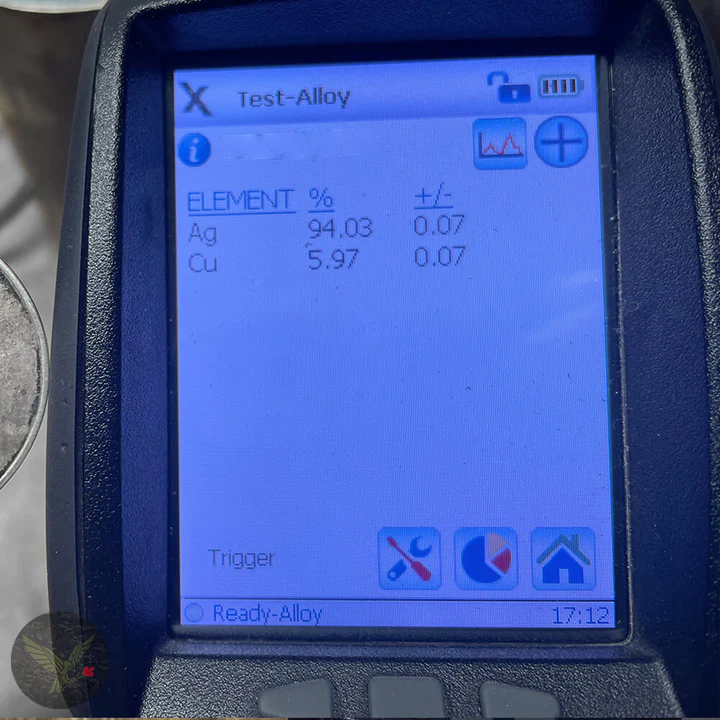

In-House Precious Metal Testing

Bring your precious metals or ore samples to us to be tested by

certified technicians using Xray Fluorescence and have the chemical

composition accurately measured and reported.

Results will include percentage of each precious metal in the sample, allowing accurate identification of purity (ie: karat grade for Gold) and/or representative sampling of ore value. Metals that can be screened for include but are not limited to Nickel, Copper, Silver, Gold, Palladium and Platinum.

This service is of value to placer miners looking to assay samples from their claims, determining the purity and value of new and heirloom jewellery, and verifying the precious metal content of metals, jewellery and coins obtained through purchase, exchange or inheritance.

Field PMI (Positive Material Identification)

Our certified XRF technicians can attend your site and perform Xray Based PMI on alloy and non-ferrous materials to ensure proper joining of metals under an API 578 or equivalent performance program.

We can also determine the composition and specification of many unknown alloys, and perform forensic audits of failed components to detect improper alloy use in construction.